______ END ______

| Siemens - SIEMENS PLM Glossary | Reference | 2022 |

| Design simulation helps manufacturers verify and validate the intended function and manufacturability of a product under development. |

| DFMA is an engineering methodology that focuses on simplifying the design of a product to improve ease of manufacture and efficiency of assembly. |

| A digital enterprise is a company where all business processes are driven by digital technology and big data. |

| Digital manufacturing is the use of an integrated, computer-based system comprised of simulation, 3D visualization, analytics and collaboration tools to create product and manufacturing process definitions simultaneously. |

| Digital transformation is the process of digitalizing business processes and information in the pursuit of a more agile and efficient business model. |

| A digital twin is a virtual representation of real-world entities and processes, synchronized at a specified frequency and fidelity. |

| Digitalization in education refers to the use of digital technology to teach students. |

| Industrial Internet of Things (IIoT), also known as Industry 4.0, is the application of an IoT framework to devices and machines within manufacturing. The IIoT is part of a larger concept known as the Internet of Things (IoT). The IoT is a network of intelligent computers, devices, and objects that collect and share huge amounts of data. The collected data is sent to a central Cloud-based service where it is aggregated with other data and then shared with end users in a helpful way. |

| The fourth industrial revolution, occurring now, is manufacturing operations digitally transformed to leverage connected data, machines, and people. A connected factory may use Additive Manufacturing (AM), cybersecurity, Artificial Intelligence (AI), Augmented Reality (AR), autonomous robots, big data analytics, cloud computing, the Internet of Things (IoT), Machine Learning (ML), simulation, and technologies not yet invented to reduce waste in their processes. |

| The manufacturing bill of materials reflects the manufacturing process of the product rather than the design of the product. mBOMs are typically driven by the eBOM and also include all items related to the end product, including packaging or shipping. |

| A system that manages as-built manufacturing information and is the authoritative source for execution records, assembly records, non-conformance records, and dimensional inspection records. It most often captures real-time data. |

| Software provides full visibility into manufacturing processes to optimize manufacturing operations performance. |

| A system that manages as-planned data and is the authoritative source for the mBOM, inventory, and equipment. |

| A methodology and system used to plan and manage manufacturing operations. The BOM for products released to manufacturing and the product routing definition are key parts of the MRP system’s database. |

| Systems Engineering is a transdisciplinary and integrative approach to enable the successful realization, use, and retirement of engineered systems, using systems principles and concepts, and scientific, technological, and management methods. |

| Physical asset configuration is a comprehensive, actionable digital twin, or virtual representation, that contains up-to-date information on the composition and structure of a managed item or property. |

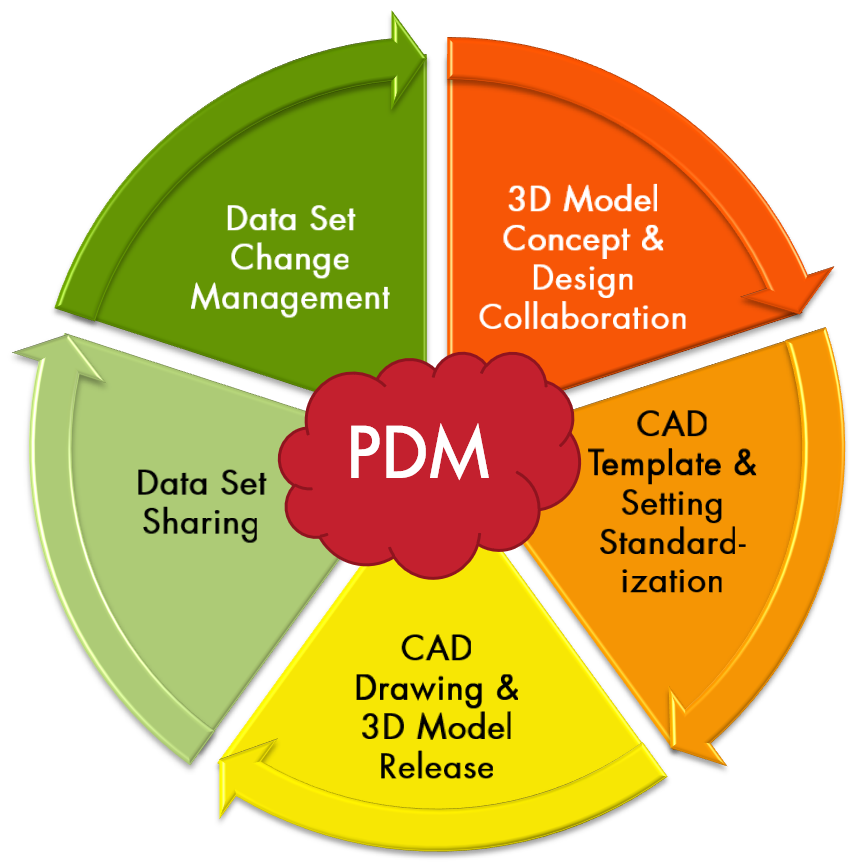

| A system that manages as-designed data and is the authoritative source for the geometry, attributes, CAD BOM, and revision. |  |

| Product Lifecycle Management Software | PLM Software |

|

| PLM software manages information throughout the entire product lifecycle from ideation, design and manufacture through service and disposal. |

| A system that manages as-inspected data and is the authoritative source for quality records. |